DMAIC is a data-driven, five step improvement cycle within the Six Sigma process. it is an excellent tool to identify root causes of problems and develop solutions. DMAIC stands for define, measure, analyze, improve, and control. The goal is to improve processes or products to achieve the Six Sigma level of 3.4 defects per million.

Six Sigma is a data-driven improvement process to eliminate defects. It was developed in the 1970s by Motorola Corporation. The goal of Six Sigma is to achieve 3.4 defects per million instances. Sigma (σ) is the Greek letter used to measure statistical variability in a process. Defects are considered anything outside of base specifications, typically derived from customer needs or manufacturing requirements. Six Sigma leverages data and statistical measures to solve problems and improve processes.

Define

Define is the first step of the DMAIC process. Under this step it is necessary to clearly define the goal of the exercise (e.g., problem, process, product). You need to also define who the customer is that is experiencing the problem and determine overall objectives. In addition, it is helpful to Define the overall process where the problem occurs.

Measure

The second step is Measure. This step focuses on objectively developing baselines and understanding deviations from the norm. This data-collection step is critical to ensure the entire process is moving in the correct direction to understand “what is happening” in the environment. An effective method to gather data and understand the problem is to “go to the spot” and see the problem first-hand.

Talk to people experiencing the problem or do the process yourself and understand what causes the problem to occur. In addition to gathering qualitative data, gather quantitative data to identify any patterns that can be statistically analyzed to identify patterns. Gathering data is critical for effective analysis using statistical tools.

Analyze

The goal of step three is to Analyze the data you gathered and determine the root cause of the problem. During this step the team needs to understand what is causing the problem, when the problem occurs, where it occurs, etc. This step requires strong critical thinking and patience to ensure a careful review of the data leads to the identification of the root cause.

Improve

Step five is to Improve; develop, implement, and test a solution for the problem. This step focuses on developing creative solutions to eliminate the root cause of the problem. Teams should use tools such as the Six Thinking Hats or Random Word to develop creative ideas. The team can leverage the plan, do, check, act (PDCA) cycle to test new ideas and determine which ideas result in improvements and eventual elimination of the problem. Within this step, the team develops new ideas, tests, then implements.

Control

The final DMAIC step is Control. The purpose of this step is to ensure improvements are sustained. It is critical to monitor the improvement steps and measure any deviations from the norm. This step is extremely important to ensure the root cause of the problem you identified eliminates the problem from reoccurring. If the problem reoccurs it is time to analyze what is occurring and develop a new solution.

Real World Example

Let’s look at a real-world example. A large chemical company sells a two-stage adhesive that bonds plastic pipes; the company sells business-to-business (B2B). The company has received a product complaint from a customer. The customer bought the two-stage adhesive to join plastic pipes and it is not working; the adhesive is gelling before the two components are mixed.

It is imperative to solve the problem and get the customer new product that is not defective. Most importantly, the customer needed a replacement, non-defective product ASAP. They have their own customers that need the product for several large projects. There is a lot of pressure to get this figured out quickly.

The team has Defined the problem and outlined the entire process from obtaining raw materials to shipping finished goods. In addition, the team has outlined three goals of the exercise.

Determine root-cause of gelling

Implement actions to verify if root-cause is issue

Develop procedures to reduce issue to zero defects

The team then gathers data to Measure the current situation. The team interviewed workers in the engineering lab, the quality lab, production areas, and the warehouses. In addition, the team called customers to understand details of the problem (when it occurred, where, etc.).

Through phone interviews it was determined there were large amounts of inventory in customer stock. In addition, the team identified that all gelling was only in batches produced from Nov 2016 to January 2017. In addition, the team then measured production levels from the past 18 months. Customer order data was gathered to understand which customers received the faulty product. The team also identified that 164 complaints of defective product was noted from five U.S. states.

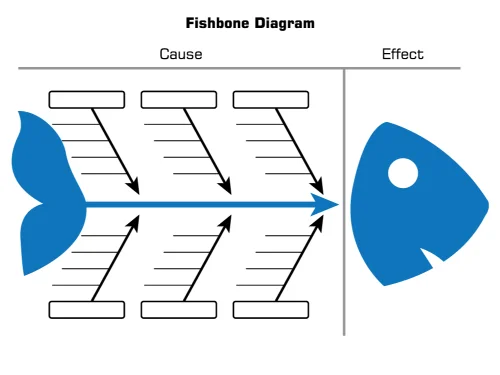

The Analysis determined that the batches used a new formula of the adhesive (the only batches to use this new formula). It was also determined that 39,899 total items were produced. As the team gathered a large amount of data, and took the time to properly analyze the data, they identified several potential root causes. A fishbone diagram was developed to graphically represent possible causes and narrow-down the most likely issues.

Within this step the team also identified that a supplier of one of the key components of the adhesive had to cease operation due to hurricane damage to their manufacturing facility. The purchasing department identified a new vendor of the same raw material to ensure production was not affected. The new raw material was quickly added to the production process to ensure all deadlines were met. Unfortunately, the raw material from the new vendor was not properly tested by the QA group before being introduced into production. The team narrowed in on the raw material as being the root cause of the gelling problem.

After analyzing all the possible causes, it was time to Improve the process and ensure the problem does not reoccur. A list of possible recommendations was developed; the focus was to eliminate the problem and ensure the customers were satisfied. The cross-functional team (engineering, quality, manufacturing, marketing, procurement) developed recommendations to avoid the problem and improve the overall process to ensure this problem is not repeated.

To ensure the problem was Controlled and the solution was effective, the team developed a new process. Each step of the process (which was noted in the Define step) had a new monitoring step added to ensure every batch produced meets specifications. And most importantly, ensure customers do not get defective products.

A quality control (QC) chart was produced and hung in the engineering lab, the quality lab, and within the production area to ensure everyone reviews and understands the new process. The goal was to ensure that any time a new material is introduced; it must be reviewed by engineering and tested by QA before using in production. This visual communication device was an excellent reminder for everyone to follow the process.

The team and senior leaders knew everyone was trying to do the right thing by making sure production was not delayed and product shipped to customers on time. This was a good example of how important it is to ensure testing is not skipped. Everyone understands that quality is the most important aspect of the business.

A town hall meeting was conducted to share the problem and solution with the entire company. The goal was to continue the development of a root-cause analysis mindset to encourage ongoing continuous improvement throughout the organization. Most importantly, the team worked together to properly go through the DMAIC process and identify the problem and develop solutions quickly, without blame. The goal was to fix the problem and ensure the customer was satisfied.

The customers were extremely impressed with the thoroughness of the analysis and the quick response from the team. In addition, the customer’s confidence was renewed to ensure the relationship continues. In addition, several members of the team visited key customers to explain what was learned, why the problem occurred, and what the company was doing to ensure this does not happen again.

Conclusion

DMAIC is an excellent process to improve existing products, processes, or services. It helps create a continuous improvement mindset throughout the organization to continually focus on eliminating defects. Using qualitative and quantitative data to drive analysis ensures a data-driven methodology is used to make critical decisions. DMAIC is easy to learn and use. If you do not have a formal root-cause analysis process, DMAIC is a great tool to use, even if the organization does not use Six Sigma.

Observe some important aspect of the marketplace or your business

Develop a tentative explanation, or hypothesis, consistent with your observations

Based on your hypothesis, make predictions

Test your predictions by conducting experiments or making further careful observations. Record your observations. Modify your hypothesis based on the new facts. If variation exists, use statistical tools to help you separate signal from noise.

Repeat steps 3 and 4 until there are no discrepancies between the hypothesis and the results from experiments and observations.

So stop guessing. Use a formal process that leverages data to make decisions. Discipline and systematic processes ensures a higher probability of success that knee-jerk reactions or a scatter-gun approach to solving problems.